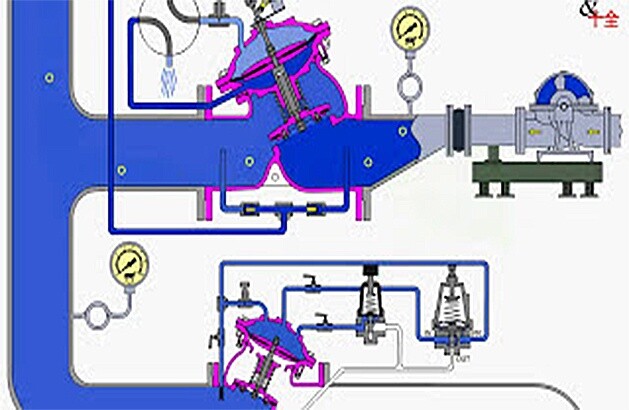

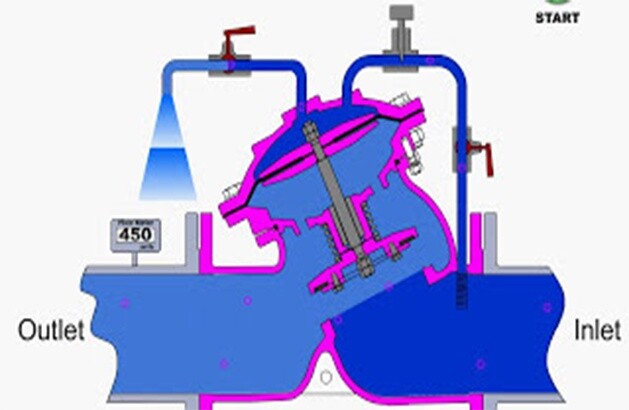

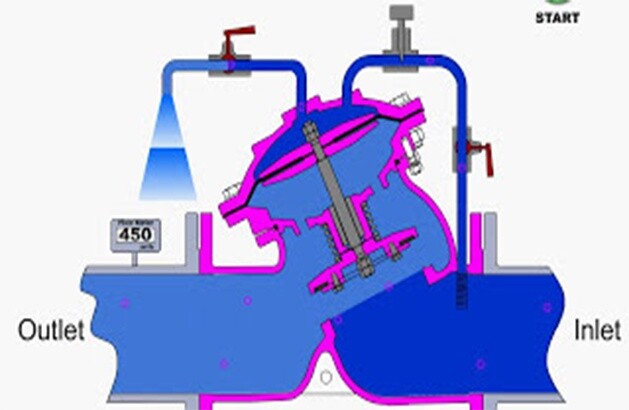

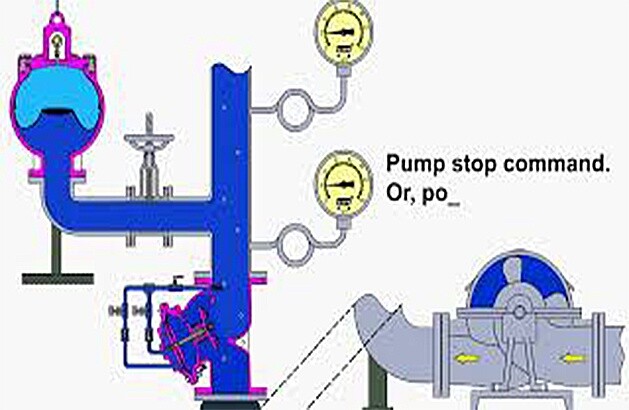

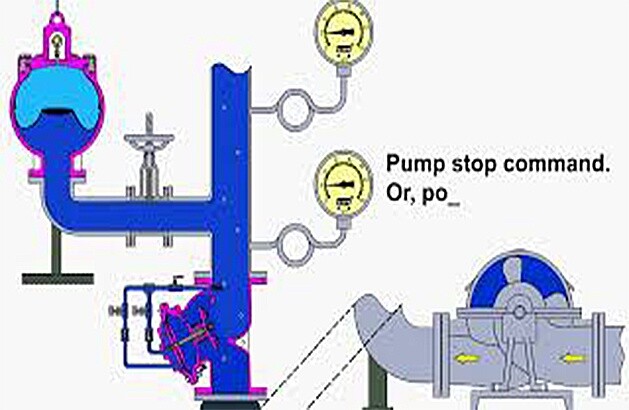

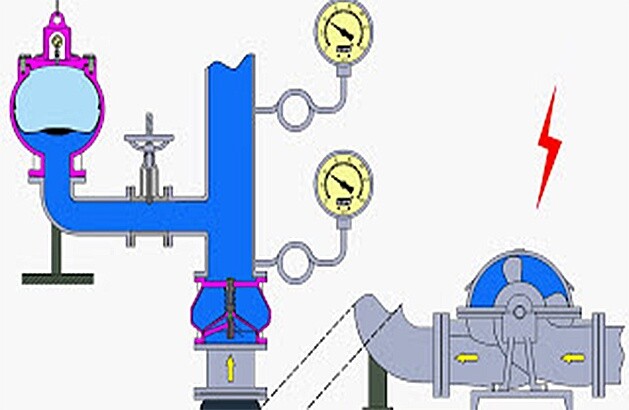

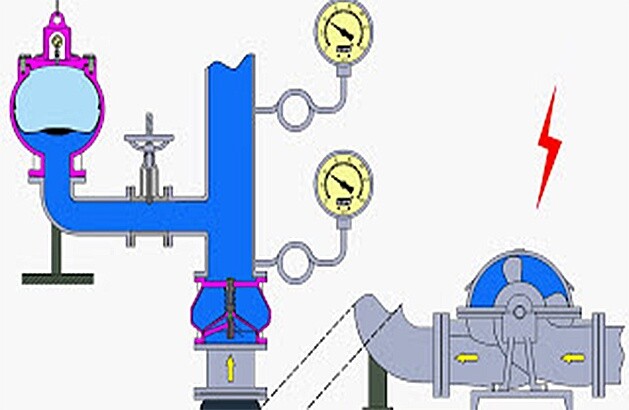

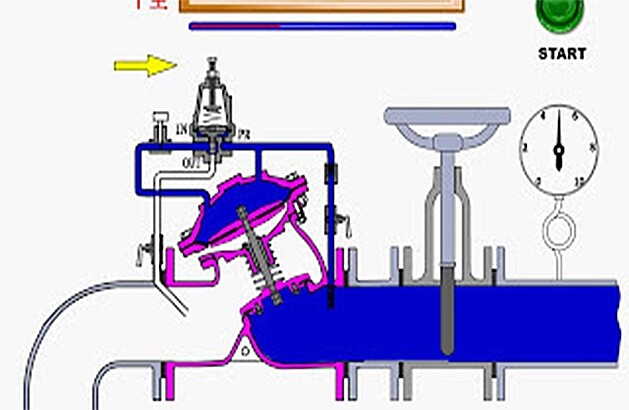

Pump Control Valve:

※ Valve uses line pressure for operation

※ Opening and closing rates adjusted separately

※ Solenoid control can be operated manually

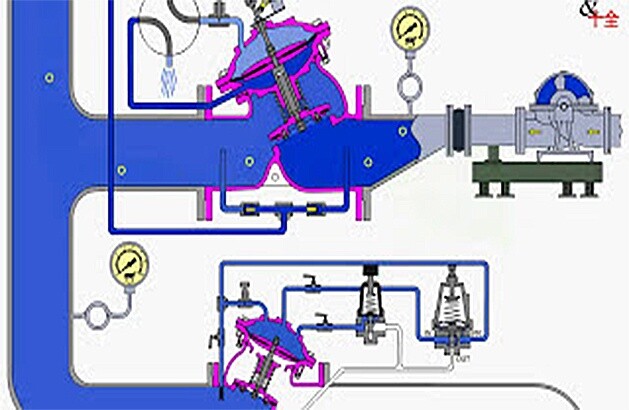

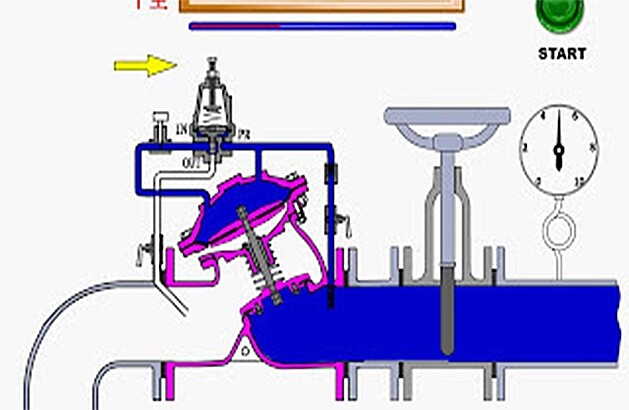

Pump Control Valve:

※ Valve uses line pressure for operation

※ Opening and closing rates adjusted separately

※ Solenoid control can be operated manually

Multi-function valve:

It has been designed to give you more than one features with one body. First, it can service as a silent check valve and shutoff valve, it also can be used as balance valve with two metering connections as standard.

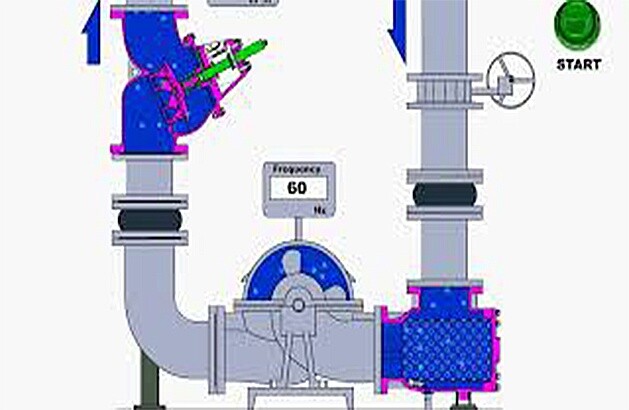

Suction Diffuser:

※ Combined more than one features in one valve, including elbow, strainer and suction stabilizer, this will save your installation space.

※ The permanent strainer provide has more free area than conventional strainers. And the percentage of the free area can be 63%.

※ Built-in straightening vanes.

※ The mesh throw-away start up strainer can prevent foreign matter from entering pump.

Multi-function valve:

It has been designed to give you more than one features with one body. First, it can service as a silent check valve and shutoff valve, it also can be used as balance valve with two metering connections as standard.

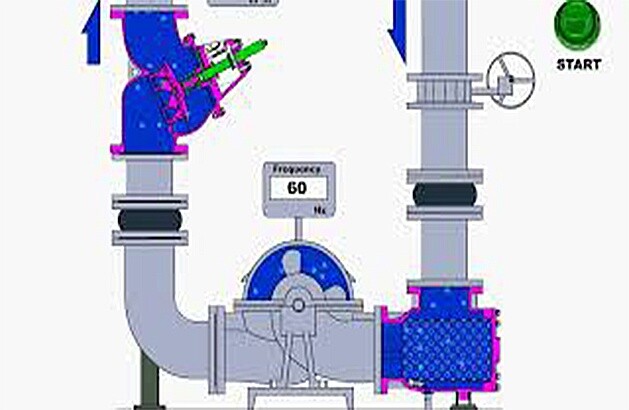

Suction Diffuser:

※ Combined more than one features in one valve, including elbow, strainer and suction stabilizer, this will save your installation space.

※ The permanent strainer provide has more free area than conventional strainers. And the percentage of the free area can be 63%.

※ Built-in straightening vanes.

※ The mesh throw-away start up strainer can prevent foreign matter from entering pump.

Water Control Valve-Basic Valve

※ Easy of Maintenance: Single Air-Chamber Set can be dismantled from the valve. No need to dismantle the whole valve

※ 25% Direct Flow: Y-Shape body design makes the valve have excellent hydromechanics.

※ Cv Value: Fluid passes through the lower part of the valve cover, so the resistance is less. Cv Value is larger than that of the Ball-Type Control Valve.

Water Control Valve-Basic Valve

※ Easy of Maintenance: Single Air-Chamber Set can be dismantled from the valve. No need to dismantle the whole valve

※ 25% Direct Flow: Y-Shape body design makes the valve have excellent hydromechanics.

※ Cv Value: Fluid passes through the lower part of the valve cover, so the resistance is less. Cv Value is larger than that of the Ball-Type Control Valve.

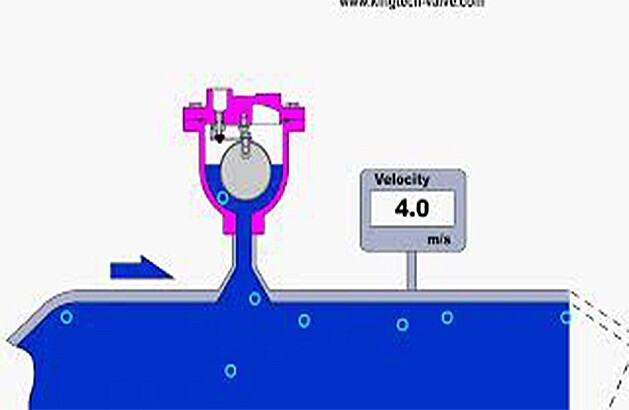

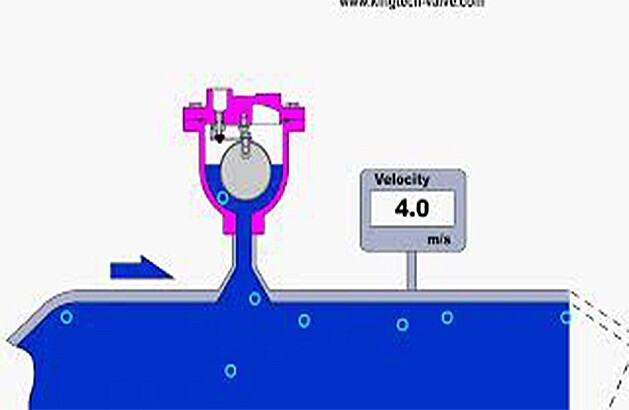

Non-Slam Check Valve:

※ Slack moving , No-Slam

※ Easy adjustment & maintain

※ Excellent reliable seal function

※ Opening velocity and closing velocity adjustment

Non-Slam Check Valve is a hydraulically operated diaphragm valve with open and close velocity control. When the pressure at the inlet exceeds the opening pressure, the valve will open gradually and slowly to prevent the surge. When a pressure reversal occurs, liquid will enter the air chamber of the valve to close the valve and form a tight seal.

Non-Slam Check Valve:

※ Slack moving , No-Slam

※ Easy adjustment & maintain

※ Excellent reliable seal function

※ Opening velocity and closing velocity adjustment

Non-Slam Check Valve is a hydraulically operated diaphragm valve with open and close velocity control. When the pressure at the inlet exceeds the opening pressure, the valve will open gradually and slowly to prevent the surge. When a pressure reversal occurs, liquid will enter the air chamber of the valve to close the valve and form a tight seal.

Micro-bubble Separator:

※ Basket type

※ Using gravity theory, flow water pass through bin, automatically separate air, water and impurity.

※ Air ejected from compound air release and vacuum valves.

※ Open bottom of valve, impurity will be ejected by pressure of water.

※ Must be installed at horizontal position.

Micro-bubble Separator:

※ Basket type

※ Using gravity theory, flow water pass through bin, automatically separate air, water and impurity.

※ Air ejected from compound air release and vacuum valves.

※ Open bottom of valve, impurity will be ejected by pressure of water.

※ Must be installed at horizontal position.

Water Hammer & Pulsation Damper:

Hydraulic shock (water hammer; fluid hammer) is a pressure surge wave caused when a fluid, in motion is forced to stop r change direction suddenly; it’s a momentum change.

This phenomenon commonly occurs when a valve closes suddenly at an end of a pipeline system, and a pressure wave propagates in the pipe. It is possible to reduce the effects of the water hammer pulses with Pulsation Damper.

Water Hammer & Pulsation Damper:

Hydraulic shock (water hammer; fluid hammer) is a pressure surge wave caused when a fluid, in motion is forced to stop r change direction suddenly; it’s a momentum change.

This phenomenon commonly occurs when a valve closes suddenly at an end of a pipeline system, and a pressure wave propagates in the pipe. It is possible to reduce the effects of the water hammer pulses with Pulsation Damper.

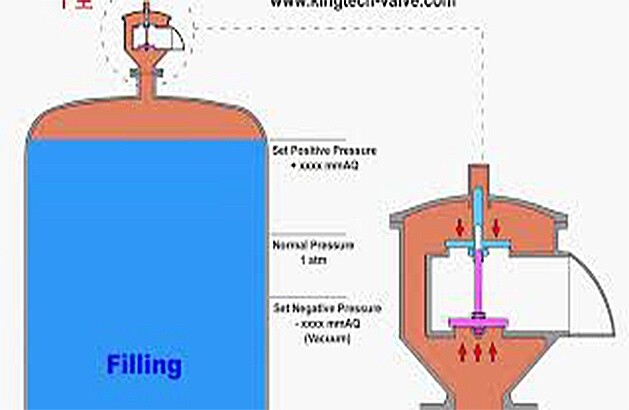

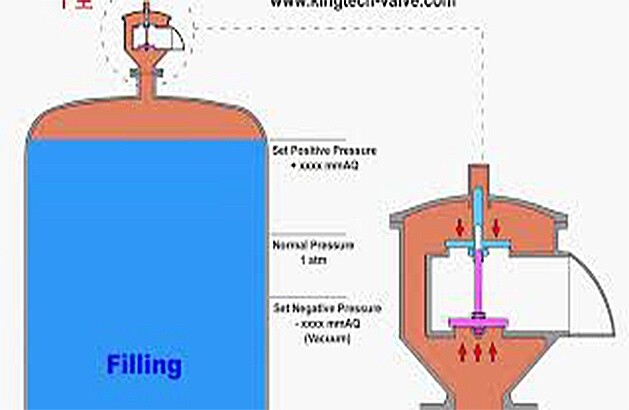

breathe valve:

Breather valve is a protective device mounted on oil or liquid tank top to prevent tank damaged due to inside air volume and pressure changed along with tank contents

increasing or losing even outside environment temperature affection.

The purpose of breather valve is mainly to control the in-breathing and out-breathing of storage tank by protecting the tank under over pressurization and vacuum and possible rupture or imploding. It is available to combine with flame arrester for fire isolation.

breathe valve:

Breather valve is a protective device mounted on oil or liquid tank top to prevent tank damaged due to inside air volume and pressure changed along with tank contents

increasing or losing even outside environment temperature affection.

The purpose of breather valve is mainly to control the in-breathing and out-breathing of storage tank by protecting the tank under over pressurization and vacuum and possible rupture or imploding. It is available to combine with flame arrester for fire isolation.

Air Release Valve:

※ Air Release Valve can quickly eliminate the air from the water.

※ All interior parts and the floating ball are made of stainless steel material.

※ l Easily maintained without special tools.

※ Large rate of flow to release the air.

Air Release Valve can eliminate the air from the water pipes to reduce the noise, vibration caused by the air. It can also maintain the stable operation of the relevant control valve, advance the efficiency of the equipment and efficiently restrain incrustations to be generated.

Air Release Valve:

※ Air Release Valve can quickly eliminate the air from the water.

※ All interior parts and the floating ball are made of stainless steel material.

※ l Easily maintained without special tools.

※ Large rate of flow to release the air.

Air Release Valve can eliminate the air from the water pipes to reduce the noise, vibration caused by the air. It can also maintain the stable operation of the relevant control valve, advance the efficiency of the equipment and efficiently restrain incrustations to be generated.

Direct-activated Pressure Relief Valve/Back Valve/Sustaining Valve:

※ When the inlet pressure directly responds to the pressure control chamber to adjust setting pressure, the response is sensitive and adjustment can be very precise.

※ The valve’s body and cover are connected with bolts and nuts instead of thread. This kind of design brings easy and tight seal.

※ The inlet pressure can be directly read form the gauge port PT 1/8″.

The valve is a diaphragm actuated pressure relief Valve. It opens automatically against the adjustable, preset spring loading whenever line pressure exceeds the setting of the spring. It is held in a normally closed position by the force of the compression spring. Effective diaphragm area is large in relation to the seat area and the action therefore is positive, precise, and dependable.

Direct-activated Pressure Relief Valve/Back Valve/Sustaining Valve:

※ When the inlet pressure directly responds to the pressure control chamber to adjust setting pressure, the response is sensitive and adjustment can be very precise.

※ The valve’s body and cover are connected with bolts and nuts instead of thread. This kind of design brings easy and tight seal.

※ The inlet pressure can be directly read form the gauge port PT 1/8″.

The valve is a diaphragm actuated pressure relief Valve. It opens automatically against the adjustable, preset spring loading whenever line pressure exceeds the setting of the spring. It is held in a normally closed position by the force of the compression spring. Effective diaphragm area is large in relation to the seat area and the action therefore is positive, precise, and dependable.

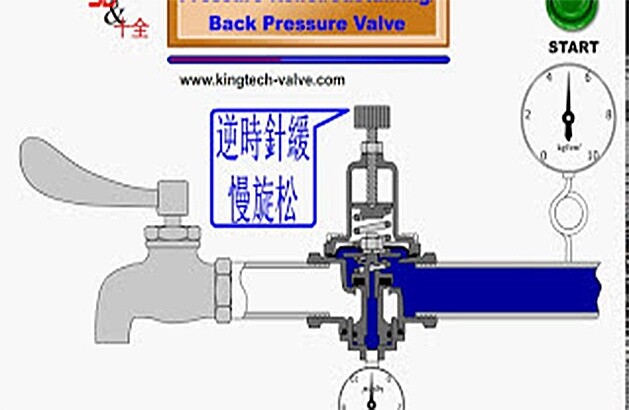

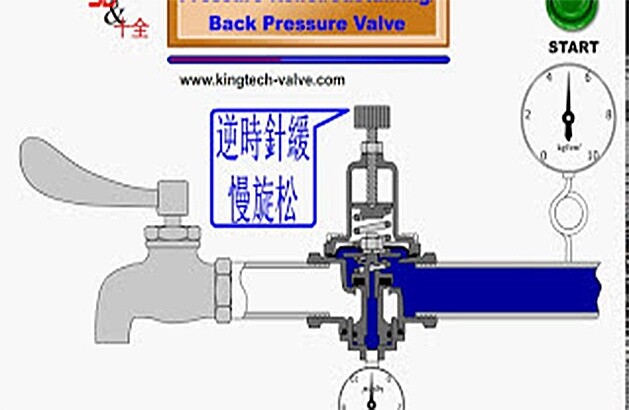

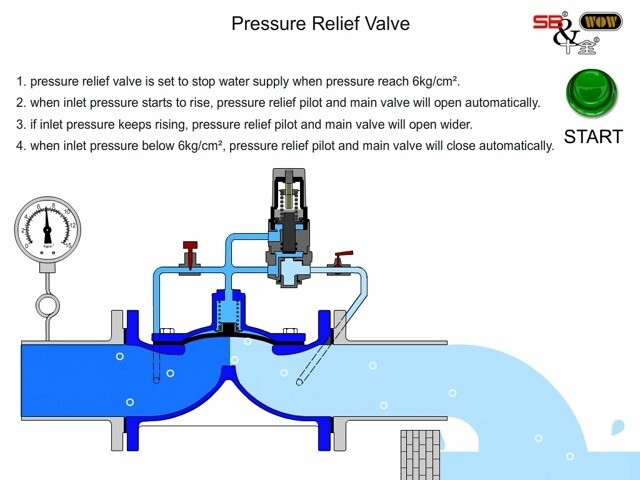

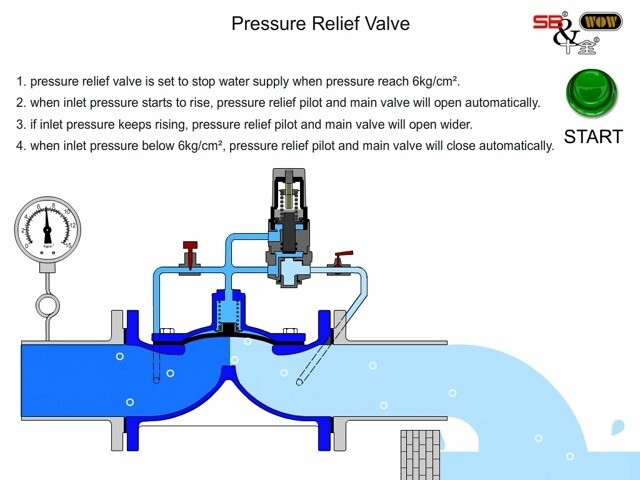

Pressure Relief Valve/Sustaining Valve/Back Valve:

※ Sensitive, accurate pressure control

※ Quickly open valve, ensure pipe pressure

※ Slow shut off design and impact prevention

※ Completely automatic operation

The pressure relief, sustaining, back pressure valve can maintain upstream pipe pressure. It is applied for pressure relief, sustaining, and back impact problems.

During operation, through pilot to sense the valve inlet pressure and control the open/close of the valve. When the input pressure is over the preset value, valve will quickly open and maintain the pressure in the pipe. After pressure relief, the valve will close slowly to prevent impact happening.

If a check feature is added, and a pressure reversal occurs, the downstream pressure is admitted in the main valve cover chamber closing the valve to prevent return flow.

Pressure Relief Valve/Sustaining Valve/Back Valve:

※ Sensitive, accurate pressure control

※ Quickly open valve, ensure pipe pressure

※ Slow shut off design and impact prevention

※ Completely automatic operation

The pressure relief, sustaining, back pressure valve can maintain upstream pipe pressure. It is applied for pressure relief, sustaining, and back impact problems.

During operation, through pilot to sense the valve inlet pressure and control the open/close of the valve. When the input pressure is over the preset value, valve will quickly open and maintain the pressure in the pipe. After pressure relief, the valve will close slowly to prevent impact happening.

If a check feature is added, and a pressure reversal occurs, the downstream pressure is admitted in the main valve cover chamber closing the valve to prevent return flow.

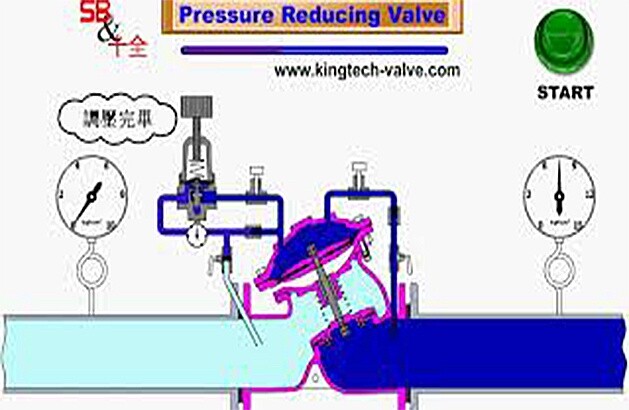

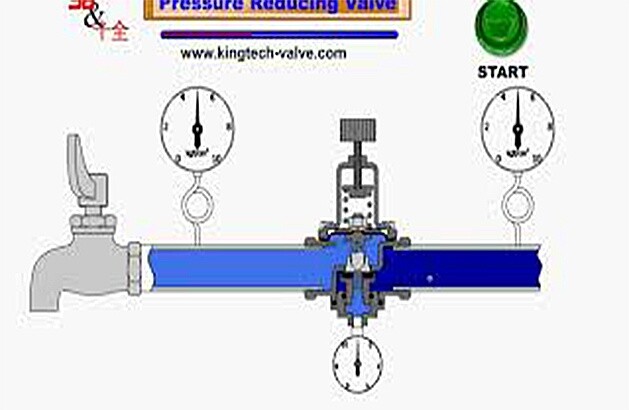

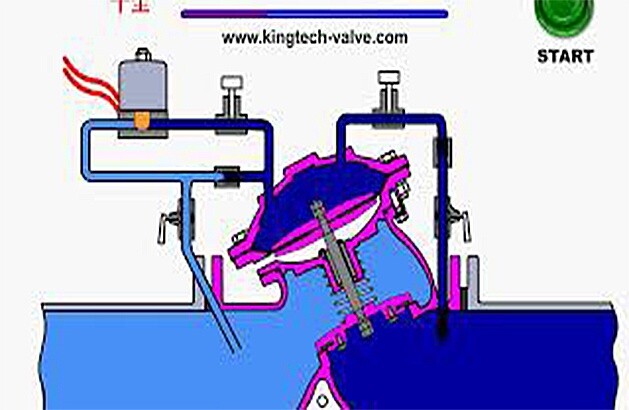

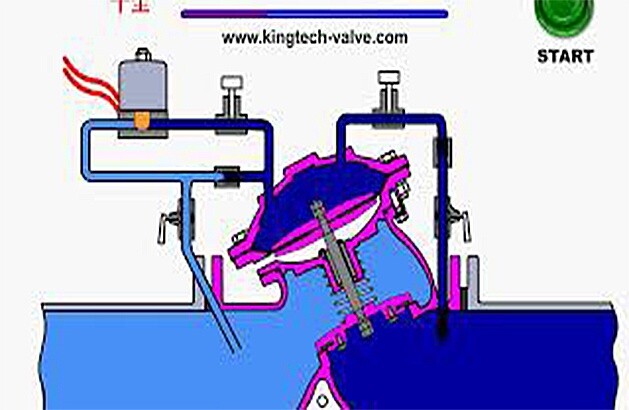

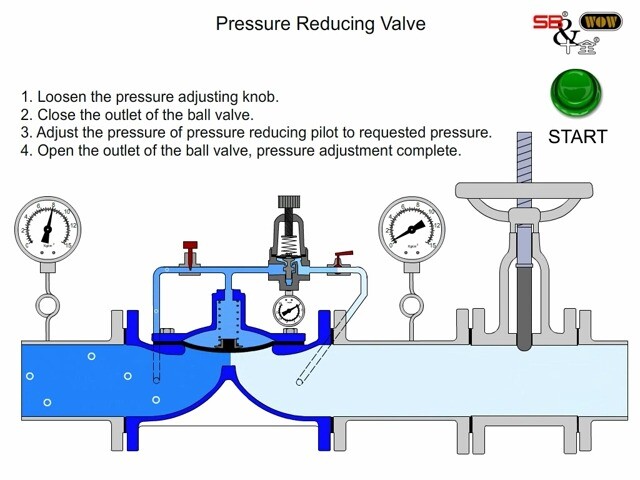

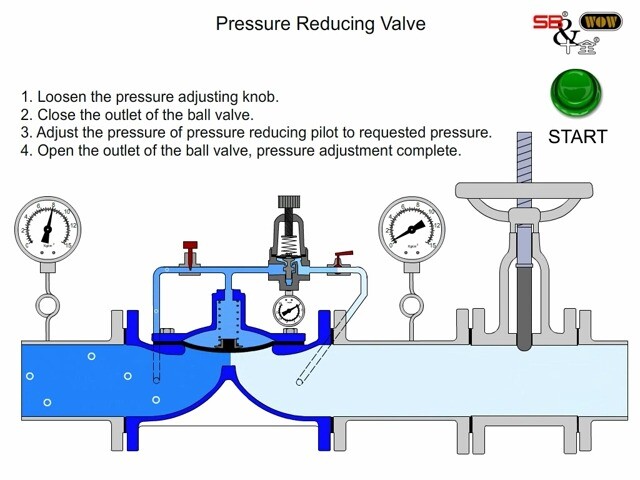

Pressure Reducing Valve:

※ Sensitive, accurate pressure control

※ Easy adjustment & maintenance

※ Reliable and excellent sealing

The pressure reducing valve can automatically reduce the inlet high pressure to the stable outlet low pressure in spite of the velocity of flow or the pressure variation. It is hydraulic pressure controlled by using a pilot controlled pressure adjuster to maintain the outlet pressure in a preset range. When the outlet pressure is over the preset range of the pressure reducing valve, the main valve and pilot will close to form a tight sealing.

If a check feature is added, and a pressure reversal occurs, the downstream pressure is admitted in the main valve cover chamber closing the valve to prevent return flow.

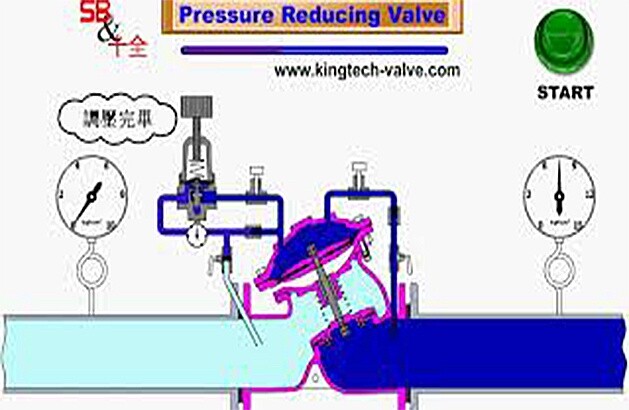

Pressure Reducing Valve:

※ Sensitive, accurate pressure control

※ Easy adjustment & maintenance

※ Reliable and excellent sealing

The pressure reducing valve can automatically reduce the inlet high pressure to the stable outlet low pressure in spite of the velocity of flow or the pressure variation. It is hydraulic pressure controlled by using a pilot controlled pressure adjuster to maintain the outlet pressure in a preset range. When the outlet pressure is over the preset range of the pressure reducing valve, the main valve and pilot will close to form a tight sealing.

If a check feature is added, and a pressure reversal occurs, the downstream pressure is admitted in the main valve cover chamber closing the valve to prevent return flow.

Direct-activated Pressure Reducing Valve:

※ The valve adopts the OPEN design, hence water supply will not be affected due to instability in inlet pressure.

※ When the outlet pressure directly responds to the pressure control chamber to adjust setting pressure, the response is sensitive and adjustment can be very precise.

※ The valve’s body and cover are connected with bolts and nuts instead of thread. This kind of design brings easy and tight seal.

※ The outlet pressure can be directly read form the gauge port PT 1/8″.

※ Can be used individually, or can be used as a pressure reducing pilot.

Direct-activated Pressure Reducing Valve:

※ The valve adopts the OPEN design, hence water supply will not be affected due to instability in inlet pressure.

※ When the outlet pressure directly responds to the pressure control chamber to adjust setting pressure, the response is sensitive and adjustment can be very precise.

※ The valve’s body and cover are connected with bolts and nuts instead of thread. This kind of design brings easy and tight seal.

※ The outlet pressure can be directly read form the gauge port PT 1/8″.

※ Can be used individually, or can be used as a pressure reducing pilot.

Solenoid Control Valve:

※ Sensitive, speedy operation

※ Adjustable shutoff speed

※ Excellent and reliable sealing performance

※ Easy adjustment and maintenance

The solenoid control valve is a valve to control open or close. It is composed of a basic valve and a solenoid switch. The powered-on pilot receives the signal to open or close the valve through the liquid inside the control air chamber of the pilot.

If a check feature is added, and a pressure reversal occurs, the downstream pressure is admitted in the main valve cover chamber closing the valve to prevent return flow.

Solenoid Control Valve:

※ Sensitive, speedy operation

※ Adjustable shutoff speed

※ Excellent and reliable sealing performance

※ Easy adjustment and maintenance

The solenoid control valve is a valve to control open or close. It is composed of a basic valve and a solenoid switch. The powered-on pilot receives the signal to open or close the valve through the liquid inside the control air chamber of the pilot.

If a check feature is added, and a pressure reversal occurs, the downstream pressure is admitted in the main valve cover chamber closing the valve to prevent return flow.

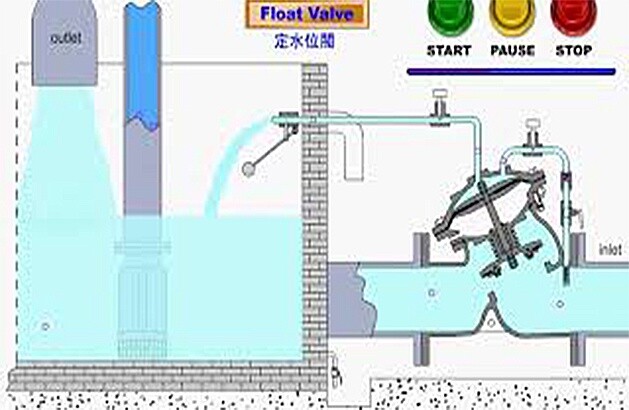

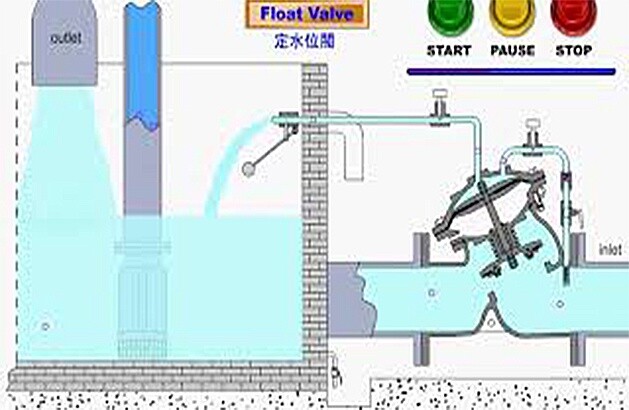

Float Valve:

※ Accurate、repeatable water level control

※ Reliable self-hydraulic pressure control

※ Tightly shut off、reliable sealing

※ Completely automatic operation

The float valve is hydraulic pressure controlled and can maintain the water level at a stable level in the tank by using a pilot to control the diaphragm control valve. The float pilot is installed at the high-water level in the tank and connected with the main valve. When the water level is changed, Pilot will open or close the valve accordingly and maintain the water level in the range.

If a check feature is added, and a pressure reversal occurs, the downstream pressure is admitted in the main valve cover chamber closing the valve to prevent return flow.

Float Valve:

※ Accurate、repeatable water level control

※ Reliable self-hydraulic pressure control

※ Tightly shut off、reliable sealing

※ Completely automatic operation

The float valve is hydraulic pressure controlled and can maintain the water level at a stable level in the tank by using a pilot to control the diaphragm control valve. The float pilot is installed at the high-water level in the tank and connected with the main valve. When the water level is changed, Pilot will open or close the valve accordingly and maintain the water level in the range.

If a check feature is added, and a pressure reversal occurs, the downstream pressure is admitted in the main valve cover chamber closing the valve to prevent return flow.

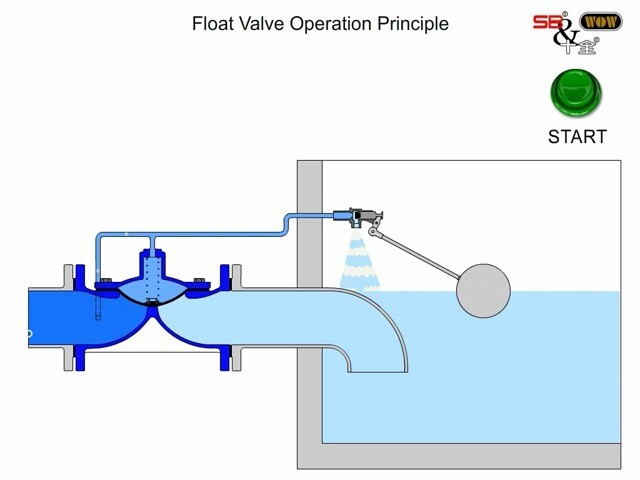

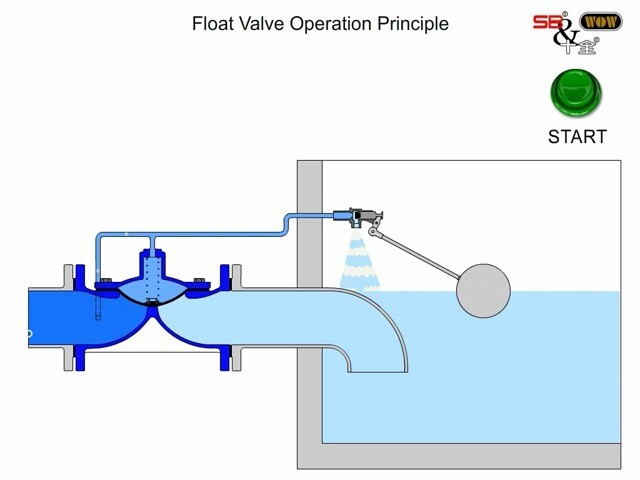

Type 47 Float Valve:

※ Accurate、repeatable water level control

※ Reliable self-hydraulic pressure control

※ Tightly shut off、reliable sealing

※ Completely automatic operation

Model 47-01 float valve is hydraulic pressure controlled and can maintain the water level at a stable level in the tank by using a pilot to control the diaphragm control valve. The float pilot is installed at the high-water level in the tank and connected with the main valve. When the water level is changed, Pilot will open or close the valve accordingly and maintain the water level in the range.

Type 47 Float Valve:

※ Accurate、repeatable water level control

※ Reliable self-hydraulic pressure control

※ Tightly shut off、reliable sealing

※ Completely automatic operation

Model 47-01 float valve is hydraulic pressure controlled and can maintain the water level at a stable level in the tank by using a pilot to control the diaphragm control valve. The float pilot is installed at the high-water level in the tank and connected with the main valve. When the water level is changed, Pilot will open or close the valve accordingly and maintain the water level in the range.

Type 47 Pressure Relief, Sustaining,Back Valve:

※ Sensitive, accurate pressure control

※ Reliable and excellent sealing

※ Quickly open valve, ensure pipe pressure

※ Slow shut off design and impact prevention

※ Completely automatic operation

Model 47-03 pressure relief, sustaining, back pressure valve can maintain upstream pipe pressure. It is applied for pressure relief, sustaining, back impact problems. during operation, through pilot to sense the valve inlet pressure and control the open/close of the valve. when the input pressure is over the preset value, valve will quickly open and maintain the pressure in the pipe. After pressure relief, the valve will close slowly to prevent impact happening.

Type 47 Pressure Relief, Sustaining,Back Valve:

※ Sensitive, accurate pressure control

※ Reliable and excellent sealing

※ Quickly open valve, ensure pipe pressure

※ Slow shut off design and impact prevention

※ Completely automatic operation

Model 47-03 pressure relief, sustaining, back pressure valve can maintain upstream pipe pressure. It is applied for pressure relief, sustaining, back impact problems. during operation, through pilot to sense the valve inlet pressure and control the open/close of the valve. when the input pressure is over the preset value, valve will quickly open and maintain the pressure in the pipe. After pressure relief, the valve will close slowly to prevent impact happening.

Type 47 Pressure Reducing Valve:

※ Sensitive, accurate pressure control

※ Easy adjustment & maintenance

※ Reliable and excellent sealing

Model 47-02 pressure reducing valve can automatically reduce the inlet high pressure to the stable outlet low pressure in spite of the velocity of flow or the pressure variation. It is hydraulic pressure controlled by using a pilot controlled pressure adjustor to maintain the outlet pressure in a preset range. When the outlet pressure is over the preset range of the pressure reducing valve, the main valve and pilot will close to form a tight sealing.

Type 47 Pressure Reducing Valve:

※ Sensitive, accurate pressure control

※ Easy adjustment & maintenance

※ Reliable and excellent sealing

Model 47-02 pressure reducing valve can automatically reduce the inlet high pressure to the stable outlet low pressure in spite of the velocity of flow or the pressure variation. It is hydraulic pressure controlled by using a pilot controlled pressure adjustor to maintain the outlet pressure in a preset range. When the outlet pressure is over the preset range of the pressure reducing valve, the main valve and pilot will close to form a tight sealing.

呼吸閥: 用於油及液體儲罐上,當外部液體輸入罐內時,罐內有大量的氣體往外呼(稱正壓)。 如罐內液體往外輸出時,罐內必須將罐外空氣吸入罐內(稱負壓)。呼吸閥用來排除罐內的正壓和負壓氣體,使罐內液體進出方便。如沒裝呼吸閥,當液體進出有障礙時,很可能出現罐體變形和震動。如停止工作時,呼吸閥自動關閉,不會把罐內液體往外洩漏,使罐內的液體質量得到有效的保障。該產品使用方便,是儲罐的必備產品。可與新型阻火器配套使用。